Understanding Packaging Neck Sizes and Industry Terms

In the packaging industry, the neck finish of a container is crucial for ensuring compatibility between bottles and closures. Understanding the dimensions and terminology associated with neck finishes helps you select the right packaging components for your product.

What Is a Neck Finish?

The neck finish refers to the top part of a bottle or jar where the closure (cap or lid) is applied. It includes the threads or other features that secure the closure to the container. The neck finish is typically specified using two numbers:

- Diameter: Measured in millimeters (mm), indicating the outer diameter of the container's neck

- Thread Style: A three-digit number representing the thread design and height.

For example, a 28-410 neck finish has a 28mm diameter and a thread style designated as 410.

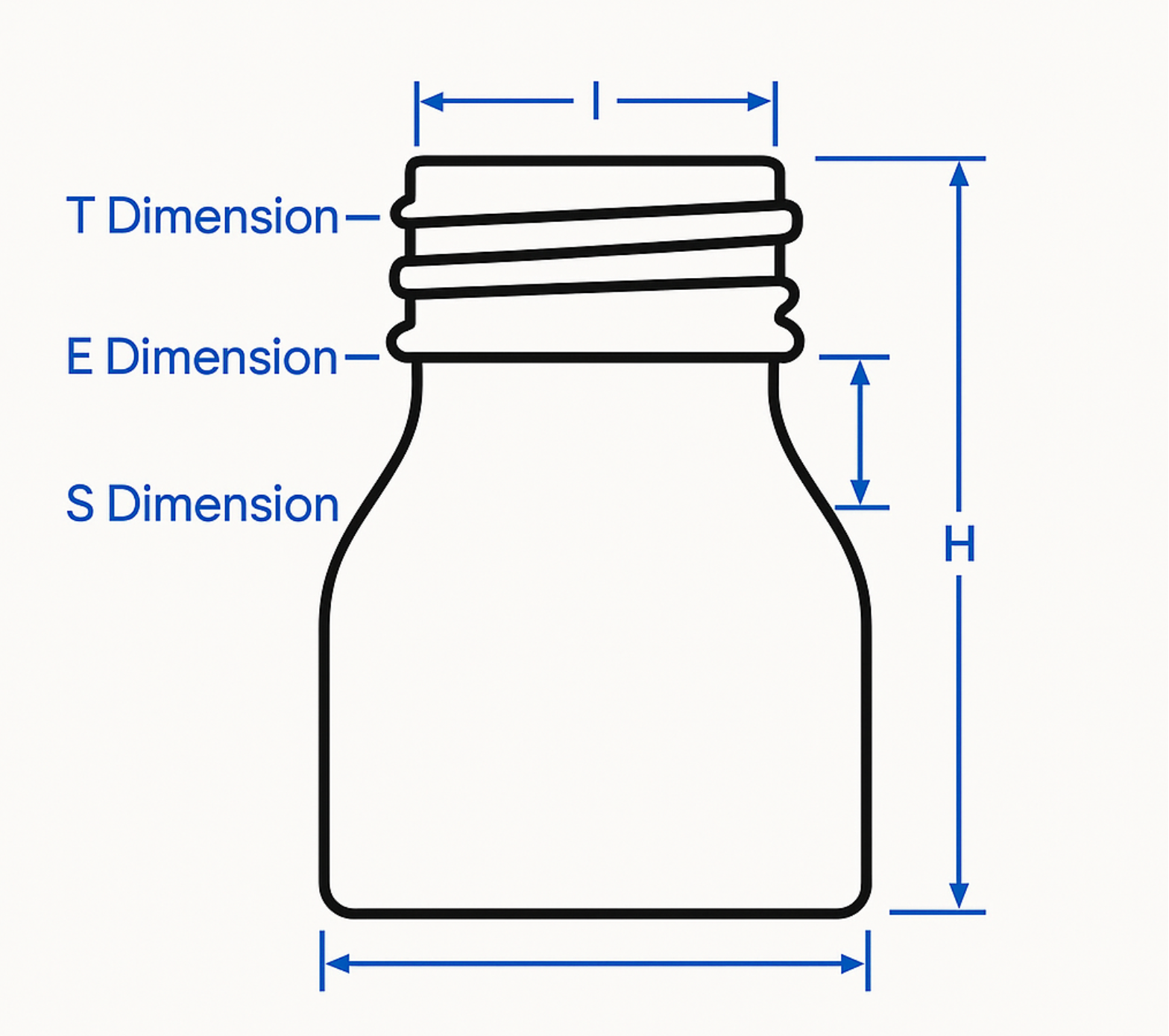

Key Neck Finish Dimensions

Understanding the specific dimensions of a neck finish is essential for ensuring proper fit and function. The following are standard measurements used in the industry

- T Dimension: The outer diameter of the neck, including threads.

- E Dimension: The outer diameter of the neck without threads.

- I Dimension: The inner diameter of the neck opening.

- S Dimension: The distance from the top of the neck to the start of the thread.

- H Dimension: The height of the neck finish from the top to where it meets the bottle's shoulder.

These dimensions are standardized by organizations such as the Glass Packaging Institute (GPI) and the Society of Plastics Industry (SPI) to ensure consistency across manufacturers.

Common Neck Finish Sizes and Applications

Different products require specific neck finishes to accommodate various closures and dispensing needs. Here are some common neck finish sizes:

- 20-410: Commonly used for small bottles (1–4 oz) in personal care products. Compatible with disc caps, flip-tops, and fine mist sprayers.

- 24-410: Versatile size for bottles ranging from 2 to 16 oz, used in cosmetics and household products. Supports a wide range of closures, including pumps and sprayers.

- 28-410: Suitable for medium-sized bottles (8–32 oz), often used for syrups and cleaning products. Compatible with pumps and trigger sprayers.

- 38-400: Used for larger containers (up to 1 gallon), such as industrial jugs and food service bottles. Supports closures like child-resistant caps and flip-tops.

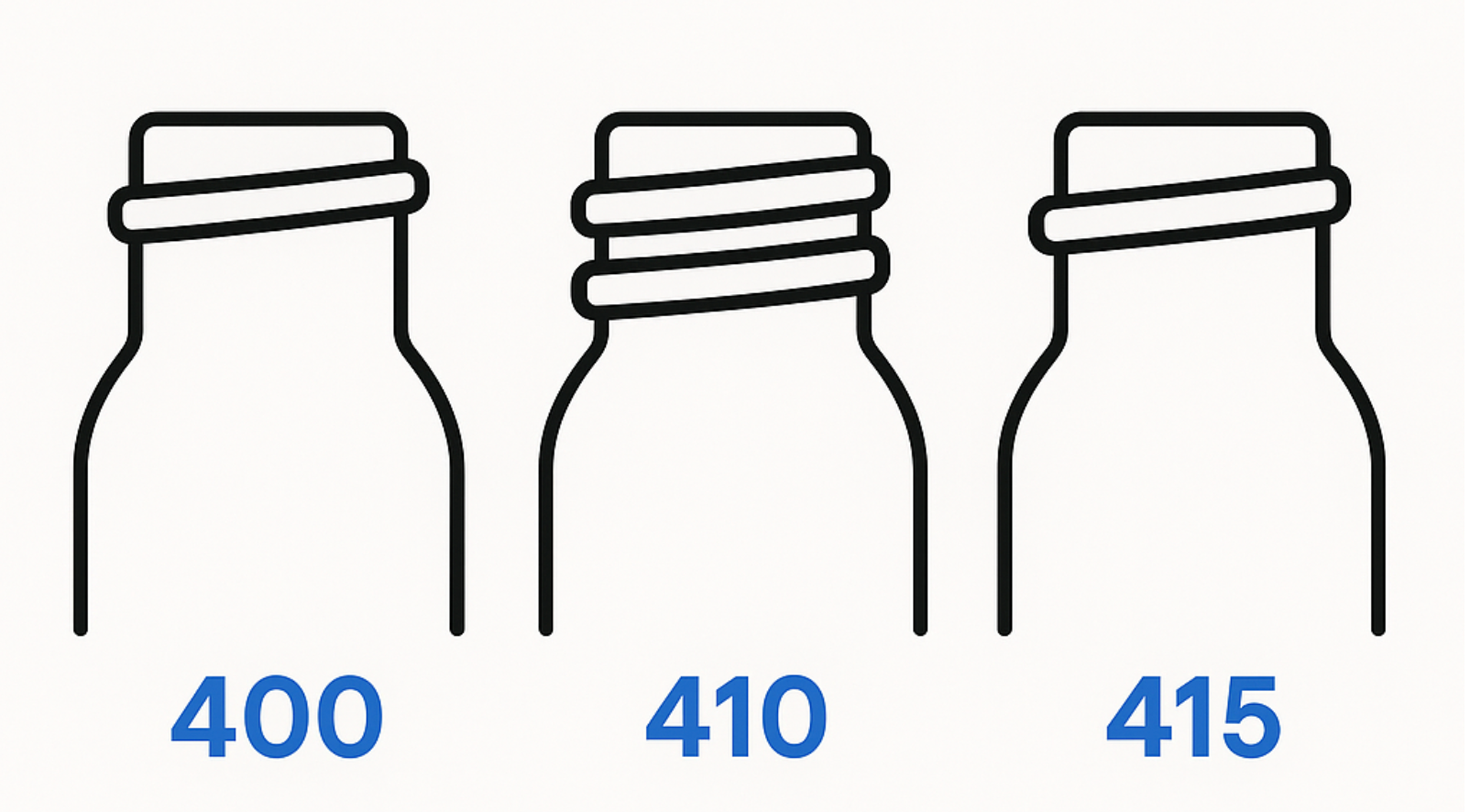

Thread Styles Explained

The thread style indicates how the closure engages with the container's neck. Common thread styles include:

- 400: Single-turn continuous thread.

- 410: One and a half turns.

- 415: Two full turns.

These styles affect the closure's sealing capability and ease of use

Measuring Neck Finishes

To determine a container's neck finish:

- Measure the T Dimension: Use calipers to measure the outer diameter of the neck, including threads.

- Identify the Thread Style: Count the number of thread turns or refer to manufacturer specifications.

Accurate measurements ensure compatibility between containers and closures, preventing leaks and ensuring product integrity.

Importance of Neck Finish Compatibility

Selecting the correct neck finish is vital for:

- Product Safety: Ensures a secure seal to prevent contamination.

- User Experience: Facilitates easy opening and dispensing.

- Regulatory Compliance: Meets industry standards for packaging

Mismatched components can lead to leaks, product degradation, and customer dissatisfaction.

By understanding packaging neck sizes and industry terminology, you can make informed decisions to ensure your product's packaging is functional, safe, and appealing to consumers.